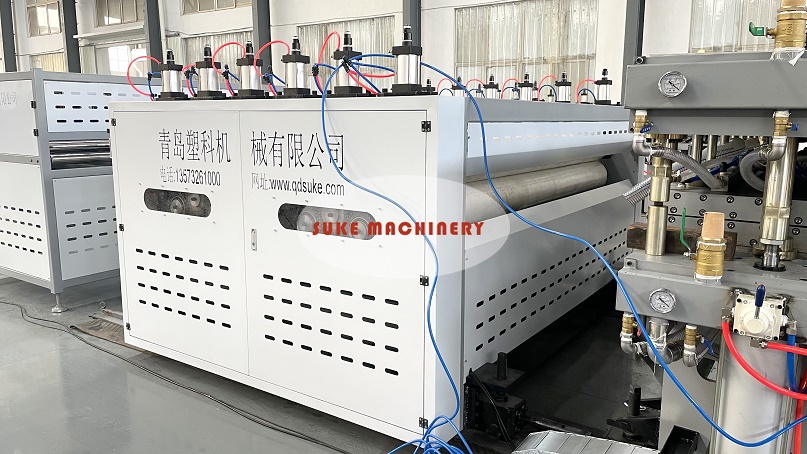

PP hollow Sheet Machine Corrugated Sheet Extruder

PP hollow sheet machine, also named pp corrugated sheet machine, is used to produce hollow/corrugated sheet which used on packing/carton application,and advertiszing industry.

- SUKE

- QIngdao

- 45 days

- 100 sets per year

- Information

What is PP hollow Sheet Machine Corrugated Sheet Extruder ?

PP hollow sheet machine/pp corrugated sheet machine can used to produce PP hollow sheet, PP corrugated sheet, PP corflute sheet.

These sheets are widely used in packaging, box making ,printing, and many kinds field.

The width of the PP hollow sheet is 1220-2800mm, and the thickness is 2mm-12mm.

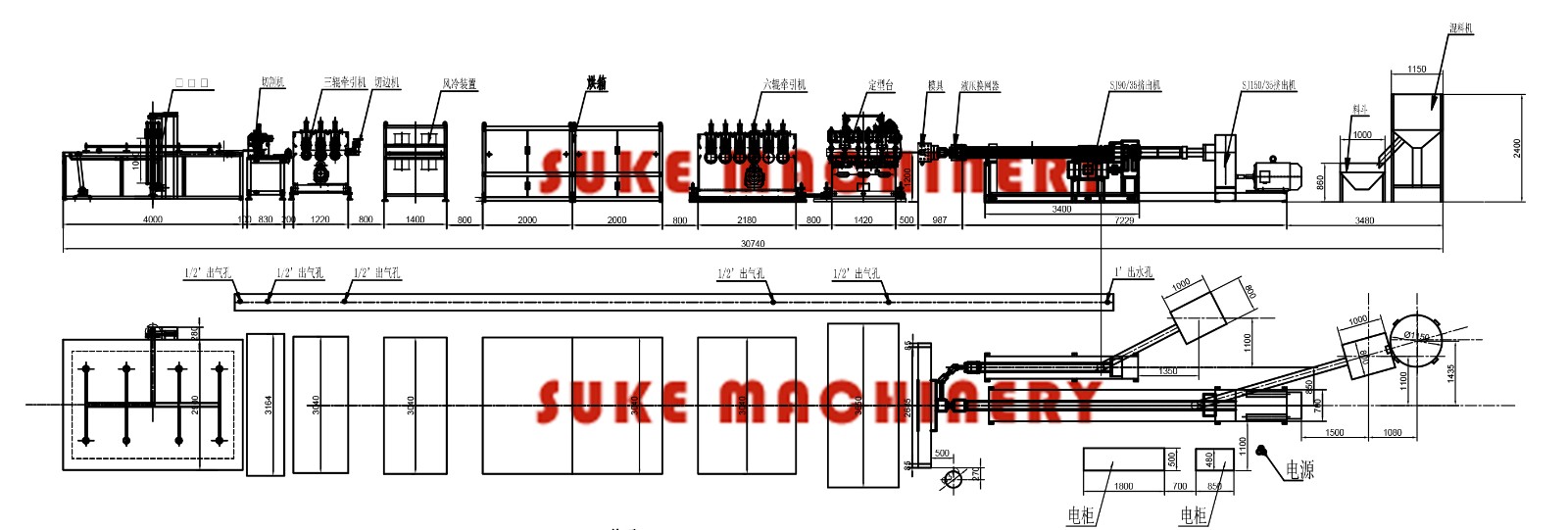

What's the equipment list of PP hollow Sheet Machine Corrugated Sheet Extruder

No. | Machine name | Quantity |

1 | Material mixing machine | 1 set |

2 | Single screw extruder | 1 set |

3 | Single screw co-extruder | 1 set |

4 | Screen changer | 1 set |

5 | Co-extruder mold:ABA | 1 set |

6 | Calibrating machine | 1 set |

7 | Six-pairs haul off machine 1st | 1 set |

8 | Preheating Oven | 2 sets |

9 | Cooling device | 1 set |

10 | Corona treatment device | 1 set |

11 | Edge cutting device | 1 set |

12 | Three-pairs haul off machine 2nd | 1 set |

13 | Transverse cutting machine | 1 set |

14 | Stacker | 1 set |

Whats' the Consist of PP hollow Sheet Machine Corrugated Sheet Extruder

1. Single screw extruder:

Inverter: ABB/Schneider/Delta

Screw: SJ110/SJ20/SJ150

Motor: 90-132kw

Temperature control : OMRON

Connector: SIEMENS

Screw Feeding.

Uniform Plasticization, Can add more than 60% Filler

2. Screen exchanger :

Used for impurity filtration.

Achieve non stop screen changing, it will improve production efficiency, save cost.

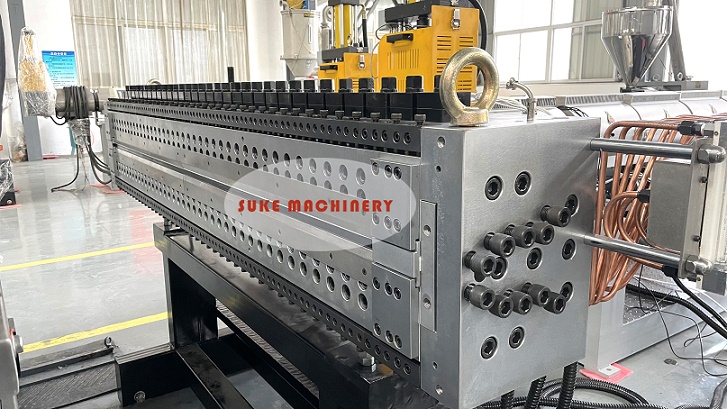

3. T-Die Mould

Width: 2300mm

Final Product width: 2100mm

Heating zone: 13 zones

Forming plate: 2 sets

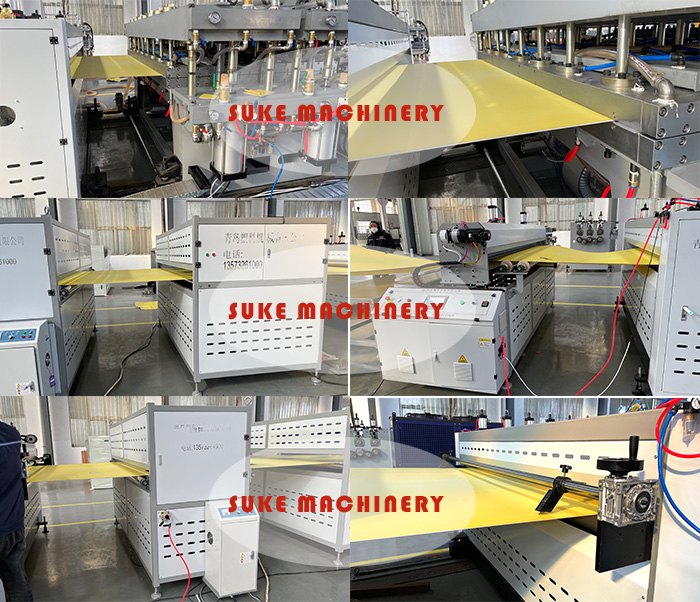

4. Calibration Machine:

Inlet pipe with valve adjustment

Vertical bar structure, stuffy fire treatment,avoid deformation

central height can be adjusted a little

2sets vacuumed system

5. Haul-off Machine

two units of hau-off machine

first one has 6 pairs of traction roll

second one has 2 pair of tractron rolll

clamp control by vacuum

6. Cutting machine

PLC Control,

Servo Motor

Traction belt moving

7. Cooling fan

For pp corrugated sheet cooling.

Cooling fun quantity: 6

8. Corona Treatment Machine

Used for corona treatment, easy for painting on final pp hollow corrugated sheet

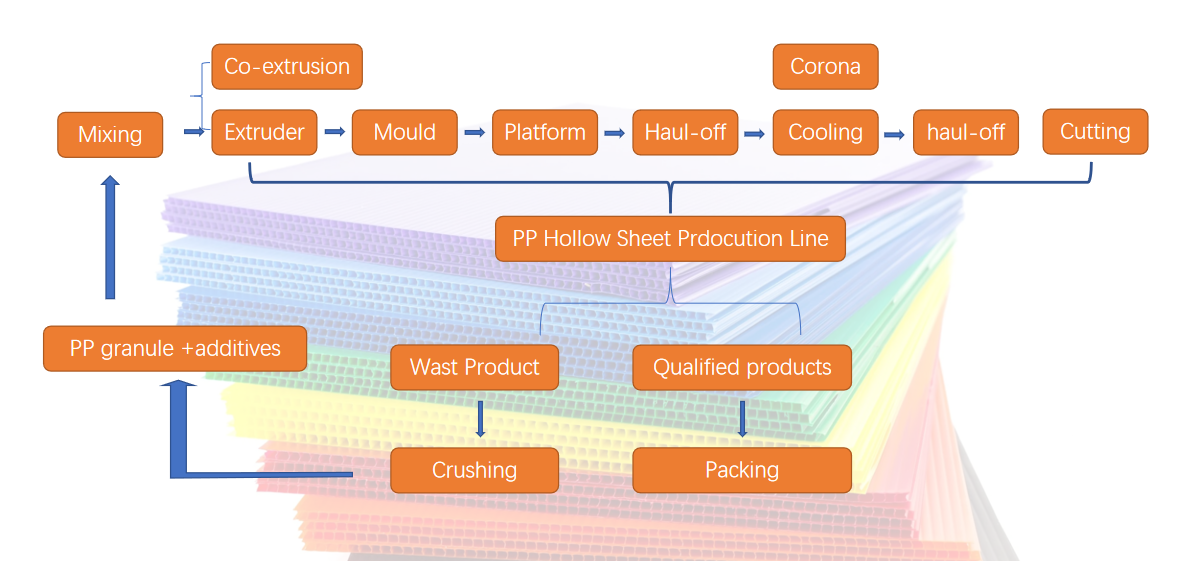

What is the process of producing the PP hollow Sheet Machine Corrugated Sheet Extruder

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder (depend on instrusion of the sheet)→Hydraulic screen change(optional)→melt pump→T-die→Vacuum calibrator forming machine→First hause off unit→Anneal oven→Cooling bracket→Double side Corona treatment device(optional)→Second haul off unit→Cross cutter and transmission unit→Collect table